Applications

Interconnection of solar cells to modules

Product marking with QR and DMC code

Laser cleaning

RFID & NFC antennas

Processing of ultra hard material

Drilling and cutting of ultra thin glass

Inside glass markung

Flexible printed circuit board

Recycling (PV and batteries)

© Bergfeld Lasertech GmbH 2020 | Roermonder Str. 110a | 52072 Aachen | Germany

bergfeld at bergfeld-lasertech.de | +49 241 4758221-0

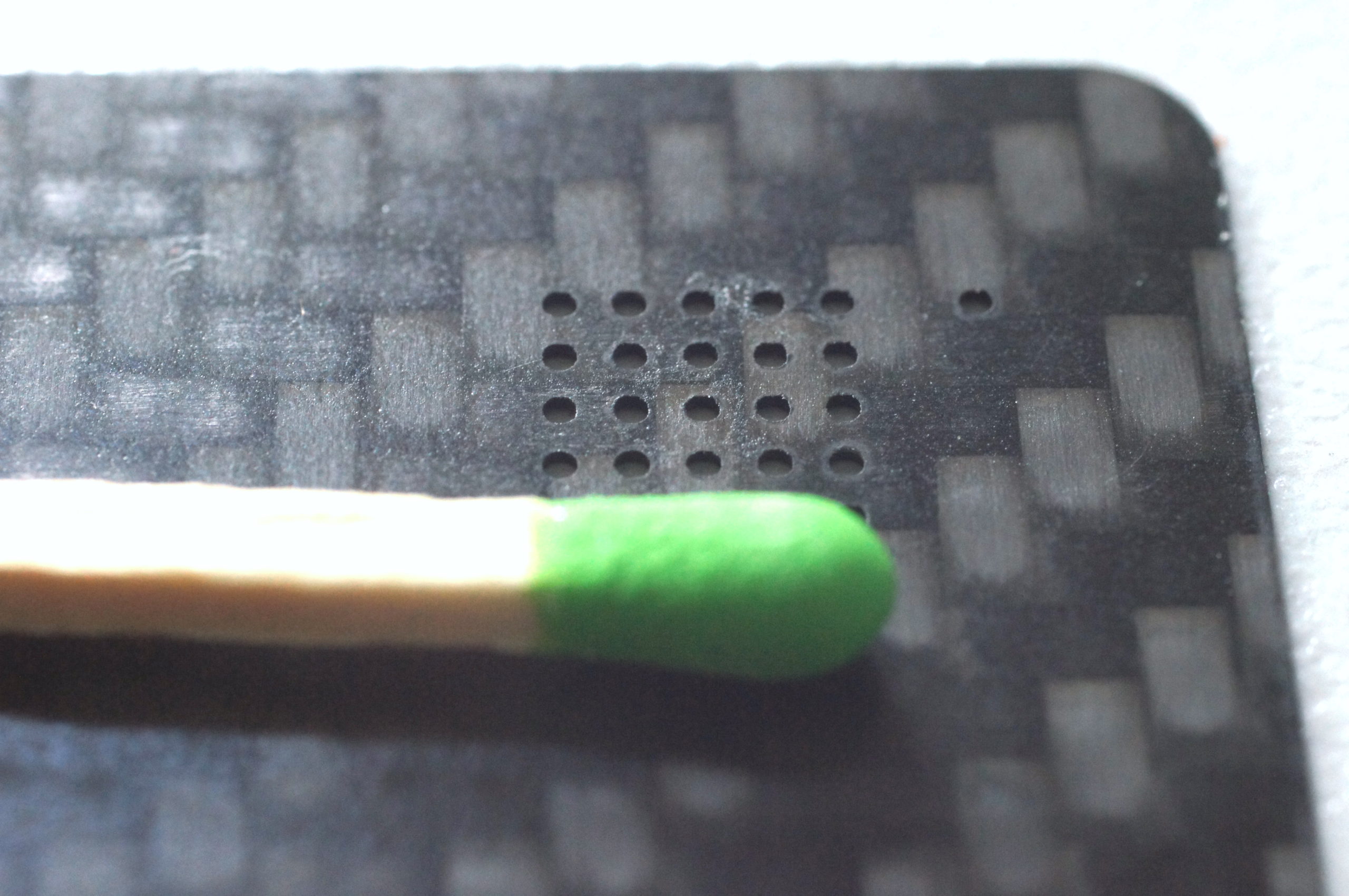

Cutting and drilling of carbon fiber reinforced plastic (cfrp)

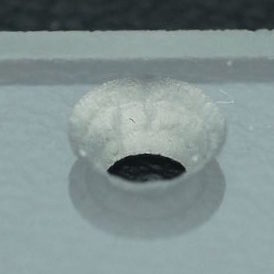

Cutting and drilling of PTFE / Teflon®

cutting, ablation, activation, patterning and structuring of battery electrodes

Material selective ablation of layers in photovoltaic (PV) moduls

The laser can remove selectively layers completely from other layers without damaging the underlying material. In this way, solar cells can be interconnected to modules. And the edges of solar modules can be completely removed to ensure a permanently stable and robust encapsulation of the module (so called "laser edge deletion"). The CIGS layer can also be removed from the molybdenum layer in order to make electrical contact with the module. In addition, each layers can be recycled seperately. The laminated solar module can be opened or delaminated with laser. The stripping of the above module was carried out with various lasers in our laboratory.

Cutting and drilling of silicon wafer

Cutting and drilling of aluminum

Marking and brightness correction of encapsulated OLED

Laser can reduce the transport of charge carriers in OLED. This can be used to brightness without damaging the OLED. Encapsulated and unencapsulated OLEDs can be provided with markings and logos or inhomogeneities in the luminance can be compensated. The efficiency of the OLED is not affected. The process is patented (DE102012113044B4). When using our rental systems to apply this process for encapsulated OLEDs for commercial purposes, a separate license from a third party is required.

Cutting and engraving of wood and paper

The shown sample was engraved and cut with an inexpensive and fast laser. The contrast of the engraving can be varied by changing the processing parameters. With other lasers fine cuts and engravings can be made without discoloration.

Removal of rust and corrosion using with laser

The laser can be used to remove corrosion and rust. In addition, protective gas can be used to avoid renewed oxidation. This enables the surfaces to be activated, for example to ensure permanent adhesion. Oxides can be generated specifically for chemical passivation.

Exposing electrical cable with a laser

Using laser radiation, the insulator can be completely removed from the metallic conductor without damaging the conductor. The process is used, for example, to weld cables at defined points. Usually the shearing takes place by means of ultrasound. Alternatively, laser welding can also be used. Laser welding also enables the connection of different metals such as copper with aluminum. With a hybrid laser process, the copper conductor can be cleaned after exposure and even chemically activated.

Laser removal of color on color

Lasers can also be used to remove colors. Depending on the type of color, different types of lasers and wavelengths are used. A special laser was used for the color in the video, which does not change the color below. Black and silver graffiti can even be completely removed from stone walls using inexpensive fiber lasers without damaging the stone.

3D laser engraving for product marking

A product marking with laser light has the advantage over inkjet printers that no consumables are required and no ink nozzles can clog. Recently, 3D laser marking systems have also been used. This allows 3D components to be marked. Such systems can also be used for non-vertical writing. This means that the number of axes of movement in machines can be reduced, undercuts can be labeled and evaporation is avoided. Some of our rental systems are equipped with 3D galvo scanners.

© Bergfeld Lasertech GmbH 2020 | Roermonder Str. 110a | 52072 Aachen | Germany

bergfeld at bergfeld-lasertech.de | +49 241 4758221-0